Geladinho Fermentation Cooling System

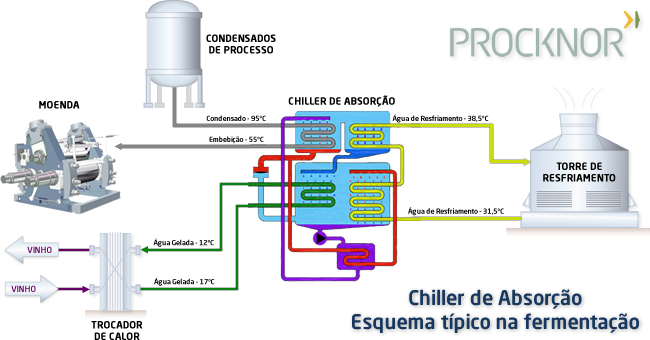

The absorption cycle is a continuous process, using heat sources of low quality (temperatures between 80C and 100C) to ensure maintenance of a given refrigerator cycle. The absorption chillers produce chilled water in the range of 15C to 22C using as primary energy sources available in the plant, such as stillage, steam condensate or vapor with temperature below 100C.

Although there are many other applications requiring chilled water in the sugarcane plants, the application that comes to mind most immediately is the use in the cooling system of fermentation. And there are strong reasons for this, including:

- The greatest individual loss of sugar in the whole process occurs in the fermentation, with efficiencies in the range of 90%. A small gain becomes a lot of money there.

- The fermentation efficiency is closely related to operating temperature in the fermenters. Experts we consulted indicated a reduction in fermentation efficiency between 0.5 and 0.8 % for each temperature grade when the fermentation operates above 33C, which is the maximum temperature that the system should operate. Practical tests indicate that the viability of yeast increases significantly when the temperature is maintained.

- Considering the trend of the market to increase ethanol production, a low efficiency will represent even more money lost.

- The agricultural frontier is directed to warmer areas, where the TBU is always higher. The TBU is the wet bulb temperature, which defines the minimum water temperature that can be obtained in the cooling towers. Moreover, “temper” the cooling water with fresh water from rivers will soon be a dying art, according to environmental constraints and the cost of water.

- It is a goal of the industry to reduce the volume of produced stillage and producing each time more concentrated stillage. The most economical way to reduce the volume of stillage is the development of microorganisms that can work in the alcoholic fermentation with the highest ethanol concentration as possible. This development is already underway, and these new microorganisms will require operation at lower temperatures.

- The harvest period in Brazil is each time bigger, which means that most often crops will be hold in the warmer months, when the losses are greater in the fermentation.

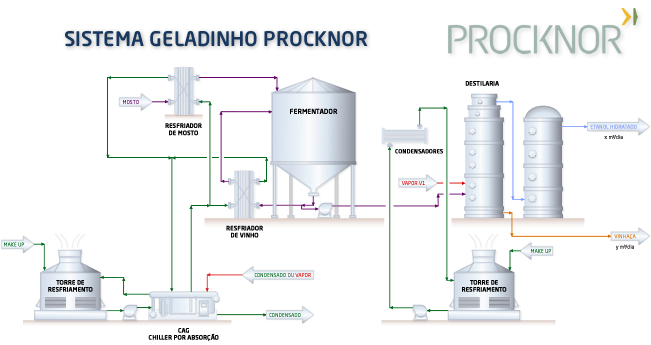

Thinking about all of these issues PROCKNOR developed the GELADINHO System. It is the application of absorption chillers to produce chilled water and the consequent ability to maintain and ensure temperatures below 33C for optimum operation of the alcoholic fermentation. The GELADINHO System can use many different sources of “poor” heat to produce chilled water, such as stillage, steam condensate and other vapours (V3 or V4).

All existing equipment in the plant (cooling towers, plate heat exchangers, pumps, etc.) can be used for the installation of the GELADINHO System. The chilled water produced by the system can also be used in other applications in the plant, such as sugar dryers and central air conditioning.